Warm Forging And Extrusion

Price

¥ 999999

Price:

Bargaining

重量

-

Product specifications

- Specifications

Remaining inventory

9999

隐藏域元素占位

- 产品描述

-

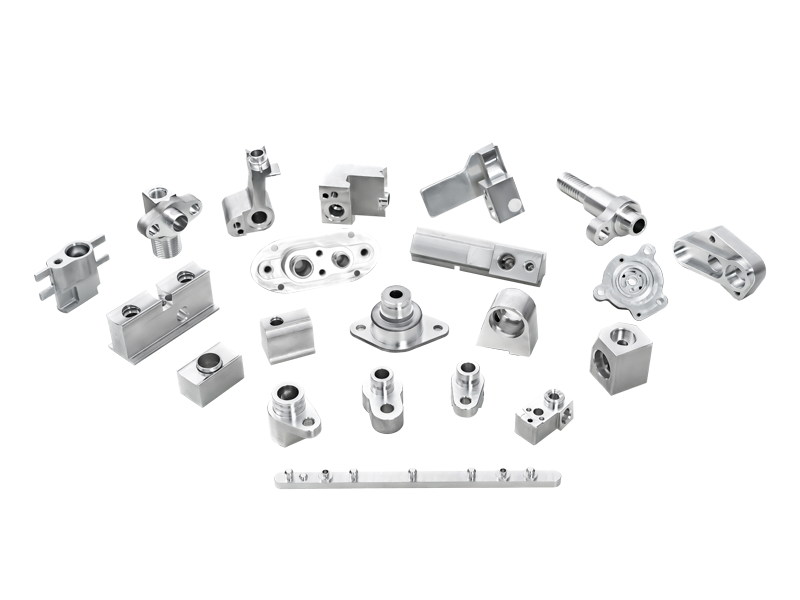

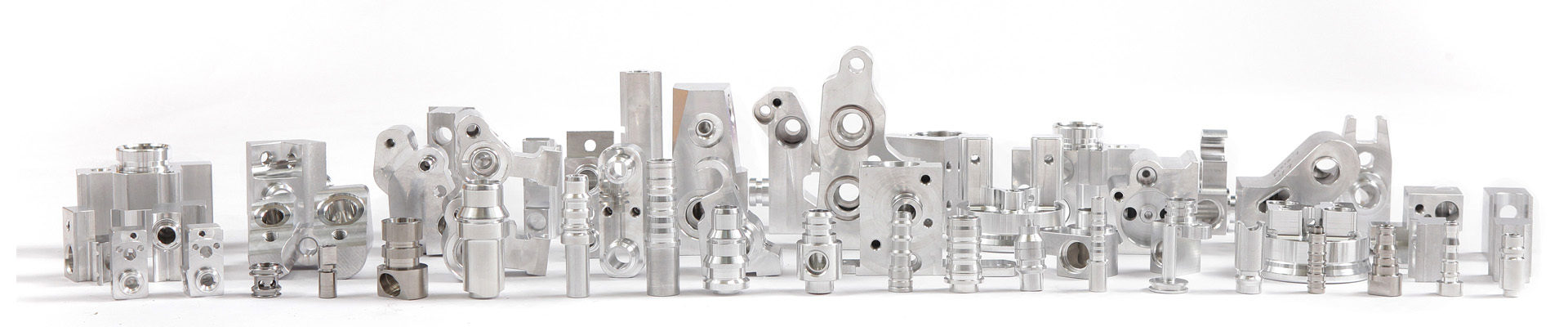

- Commodity name: Warm Forging And Extrusion

Extrusion is a process that forces the metal block to produce plastic flow and manufactures hollow parts or parts with a cross-section smaller than that of the blank through the gap between the punch and the die or the outlet of the die. It is called warm extrusion that the blank is heated to a temperature below the recrystallization temperature for extrusion. Warm extrusion also features the advantage of few chips. In particular, materials that are difficult to machine at room temperature may become machinable or easy to machine during warm extrusion, such as stainless steel with precipitation hardening phase, high-carbon steel, some steels with a high chromium content, high-temperature alloys, etc. Warm extrusion is not only applied for materials that feature high deformation resistance and are hard to machine, i.e., low-carbon steel suitable for cold extrusion, but also suitable for warm extrusion objects, because extrusion facilitates organization of continuous production. Warm extrusion is applicable to great deformation, which can reduce the number of processes.

Extrusion is a process that forces the metal block to produce plastic flow and manufactures hollow parts or parts with a cross-section smaller than that of the blank through the gap between the punch and the die or the outlet of the die. It is called warm extrusion that the blank is heated to a temperature below the recrystallization temperature for extrusion. Warm extrusion also features the advantage of few chips. In particular, materials that are difficult to machine at room temperature may become machinable or easy to machine during warm extrusion, such as stainless steel with precipitation hardening phase, high-carbon steel, some steels with a high chromium content, high-temperature alloys, etc. Warm extrusion is not only applied for materials that feature high deformation resistance and are hard to machine, i.e., low-carbon steel suitable for cold extrusion, but also suitable for warm extrusion objects, because extrusion facilitates organization of continuous production. Warm extrusion is applicable to great deformation, which can reduce the number of processes.

Previous

Next

Related Products

If you are insterested in our products.Please leave a message below,and we will contact you immediately.

JOIN US

Employees are the foundation of PXI. We attach importance to and respect the development of employees.

Mobile Website

PXI Auto Components

E-mail:szzjdb@pxi-automotive.com

Tel:+86-512-52413673

Add:1 North Lu, Changshu City, Suzhou, Jiangsu Province, China

Copyright © 2023 PXI Auto Components (Suzhou) Co., Ltd